SSD (solid-state drive) Definition

An SSD (solid-state drive) is a type of nonvolatile storage media that stores persistent data on solid-state flash memory. Two key components make up an SSD: a flash controller and NAND flash memory chips. The architectural configuration of the SSD controller is optimized to deliver high read and write performance for both sequential and random data requests. SSDs are sometimes referred to as flash drives or solid-state disks.

Unlike a hard disk drive (HDD), an SSD has no moving parts to break or spin up or down. A traditional HDD consists of a spinning disk with a read/write head on a mechanical arm called an actuator. The HDD mechanism and hard disk are packaged as an integrated unit. Businesses and computer manufacturers have used spinning disk historically, owing to their lower unit cost and higher average durability, although SSDs are now common in desktop and laptop PCs.

A spinning HDD reads and writes data magnetically, which is one of the oldest storage media in continuous use. The magnetic properties, however, can lead to mechanical breakdowns. An SSD, conversely, reads and writes the data to a substrate of interconnected flash memory chips, which are fabricated out of silicon. Manufacturers build SSDs by stacking chips in a grid to achieve varying densities.

To prevent volatility, SSD manufacturers design the devices with floating gate transistors (FGRs) to hold the electrical charge. This allows an SSD to retain stored data even when it is not connected to a power source. Each FGR contains a single bit of data, designated either as a 1 for a charged cell or a 0 if the cell has no electrical charge.

SSD history, emergence in enterprise storage

The earliest solid-state drives generally were designed for consumer devices. The debut of the Apple iPod in 2005 marked the first notable flash-based device to broadly penetrate the consumer market.

EMC — now known as Dell EMC — is credited with being the first vendor to include SSDs in enterprise storage hardware when it added the technology to its Symmetrix disk arrays in 2008. That spawned the advent of hybrid flash arrays that combine flash drives and HDDs. For the most part, enterprise SSDs in hybrid arrays are used for caching reads in flash. This is due to the higher cost and lower endurance of SSDs when compared to HDDs.

The earliest commercially designed SSDs were made with enterprise multi-level cell (enterprise MLC) flash technology, which has enhanced write cycles compared to consumer-grade MLC. Newer enterprise SSDs are being marketed that use triple-level cell (TLC). SSDs made with 3D NAND represent the next evolution. IBM, Samsung and Toshiba have produced and marketed SSDs with 3D NAND, in which flash memory cells are stacked atop one another in vertical layers. Toshiba sold off its flash chip business in 2017.

Enterprise adoption of flash is on the rise as a result of improvements in solid-state wear performance and falling flash prices, although tightening global flash supplies have stalled the price drop. Experts contend SSDs are starting to supplant traditional disk in some use cases, although flash drives and HDDs are expected to coexist in many enterprises for the foreseeable future. For example, SSDs are geared for high-performance storage, but less so for long-term archiving and backup, which typically use fixed disk.

The following video offers advice on the most important things to consider before installing an SSD in your organization.

What are solid-state drives used for?

SSDs provide faster storage and other performance benefits than fixed disk. Businesses with a rapidly expanding need for higher input/output (I/O) have fueled the development and adoption of SSDs. Because SSDs offer lower latency than HDDs, they can efficiently handle both heavy read and random workloads. That lower latency stems from the ability of a flash SSD to read data directly and immediately from a specific flash SSD cell location.

An all-flash array takes only SSDs as storage. A hybrid flash array combines disk storage and SSDs with the flash used to cache hot data that is later written to disk or tape. In server-side flash configurations, SSDs are installed in x86 computers to support targeted workloads, sometimes in conjunction with networked storage.

High-performance servers, laptops, desktops or any application that needs to deliver information in real time or near real time can benefit from solid-state drive technology. Those characteristics make enterprise SSDs suitable to offload reads from transaction-heavy databases, to alleviate boot storms with virtual desktop infrastructure (VDI), or inside a storage array to stage hot data locally for off-site storage in a hybrid cloud scenario.

SSDs are used in a range of consumer devices, including computer games, digital cameras, digital music players, laptops, PCs, smartphones, tablets and thumb drives. These devices are not engineered to provide the same level of performance or durability as an enterprise SSD.

Major features

Several features characterize the design of an SSD. Because it uses no moving parts, an SSD is not subject to the mechanical failure that occurs with HDDs. It is also quieter and consumes less power than its disk counterpart. And because SSDs weigh less than hard drives, they are good fits for laptop and mobile computing devices.

In addition, the SSD controller software includes predictive analytics that alert a user in advance of a potential drive failure. Because flash memory is malleable, all-flash array vendors can manipulate the usable storage capacity with data reduction techniques.

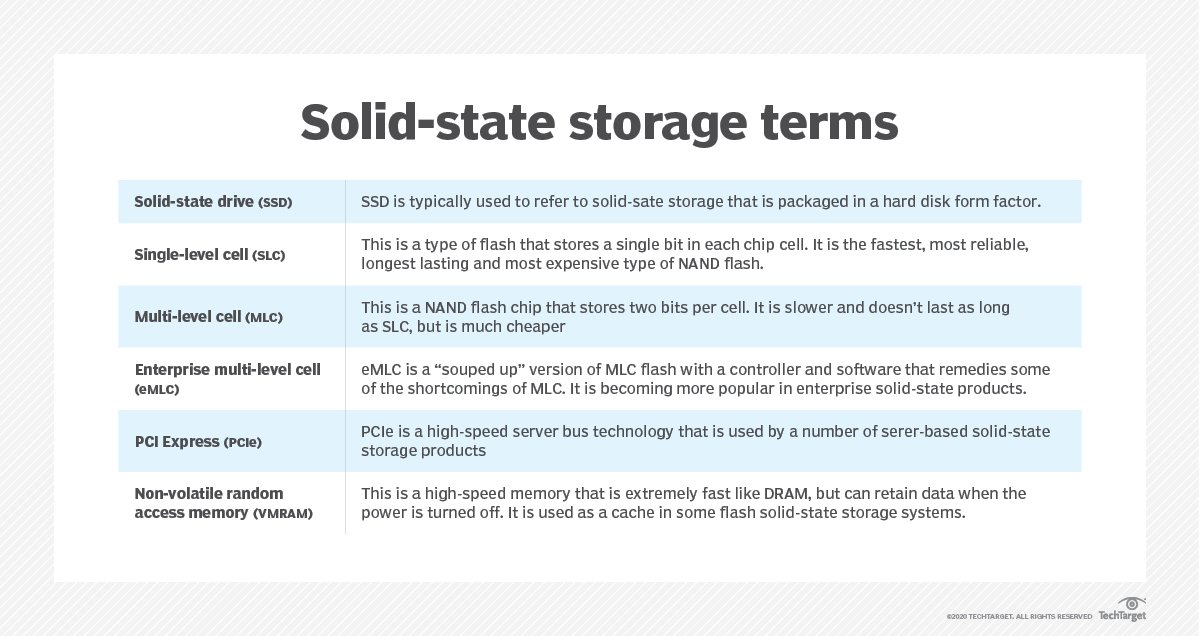

SSDs usually are built with single-level cell (SLC) or MLC flash memory. SLC drives store 1 bit of data per cell of flash media. MLC-based SSDs double the drive capacity by writing data in two segments. Newer SSDs, known as TLC, are being marketed that store 3 bits of data per flash cell. TLC is less expensive than SLC or MLC, which makes it an attractive option for manufacturers of consumer-based flash devices. TLC-based SSDs deliver more flash capacity and are cheaper than MLC or SLC, albeit with a higher likelihood for bit rot due to having eight states within the cell.

SSD lifespan vs. HDD

A number of factors influence the lifespan of SSDs and HDDS, including humidity and the effect of metals oxidizing inside in the drives. Data on both types of media will degrade over time, with HDDs generally supporting a higher number of drive writers per day.

As noted, the moving parts of HDDs increase the chance of failures. To compensate, HDD manufacturers will add shock sensors to protect drives and other components inside personal computing devices. This type of sensor uses piezoresistors to detect if the machine is about to fall and will then take steps to shut down the HDD and related critical hardware.

Heat exposure is another factor affecting a drive’s life, especially for SSDs. Industry experts recommend storing unused or idle SSDs at low temperatures to extend their life. When an SSD operates at high temperatures for a sustained period of time, it can contribute to electrons leaking from the NAND flash memory.

Flash supports a limited number of drive writes per day. The level of data retention decreases as more and more data is written to the flash cells. Enterprise SSDs are engineered with greater endurance than consumer SSDs.

SSD form factors

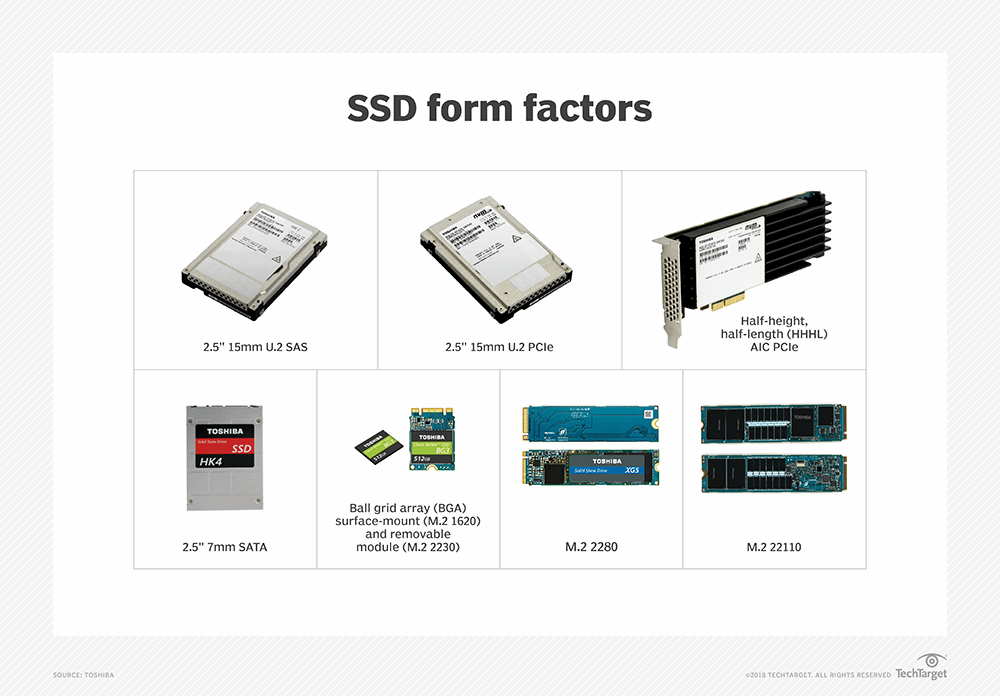

SSDs don’t have the physical constraints of HDDs. This enables drive manufacturers to offer SSDs in diverse form factors. The most common form factor is a 2.5-inch SSD that is available in multiple heights and that supports serial-attached SCSI (SAS), Serial Advanced Technology Attachment (SATA) and nonvolatile memory express (NVMe) protocols.

The Solid State Storage Initiative (SSSI), a project of the Storage Networking Industry Association (SNIA), has identified three major SSD form factors for the enterprise.

- SSDs that come in traditional HDD form factors and fit into the same SAS and SATA slots in a server.

- Solid-state cards that use standard add-in card form factors, such as those that use a Peripheral Component Interconnect Express (PCIe) serial port card that resides on a printed circuit board. A PCIe-connected SSD does not require network host bus adapters (HBAs) to relay commands, which speeds the performance of storage. These devices include U.2 SSDs that are generally considered the eventual replacement for the miniSATA drives presently used in thin laptops.

- Solid-state modules that reside in a dual in-line memory module (DIMM) or small outline dual in-line memory module (SO-DIMM), and may use a standard HDD interface such as SATA. These devices are known as nonvolatile DIMM (NVDIMM) cards.

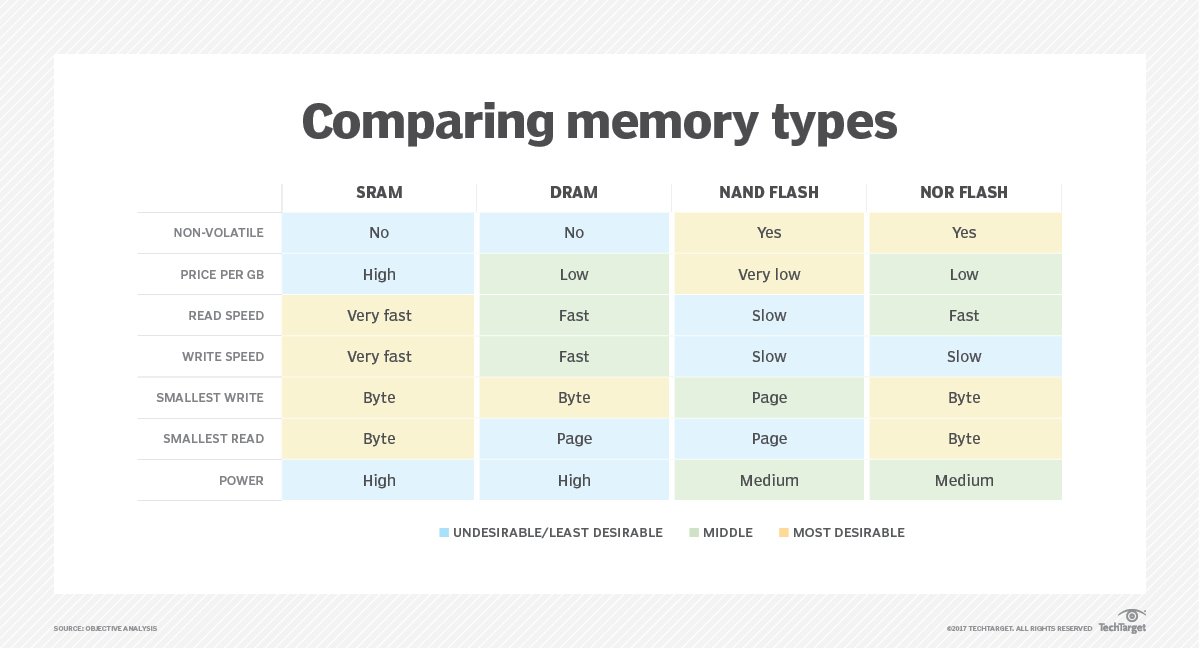

Two types of random-access memory (RAM) are used in a computer system: dynamic random access memory (DRAM), which loses data when power is lost, and static random access memory (SRAM). NVDIMMs provide the persistent storage a computer needs to recover data. An NVDIMM places flash close to the motherboard, but operations are carried out in DRAM. The flash component slots into a memory bus for backup on high-performance storage.

Both SSDs and RAM incorporate solid-state chips, but the two memory types function differently within a computer system. As noted, flash memory is a storage medium, while RAM is active memory that carries out the calculations of data retrieved from storage.

There are two newer form factors worth noting: M.2 and U.2 SSDs. An M.2 SSD varies in length — typically from 42 millimeters to 110 millimeters — and attaches directly to a motherboard. It communicates via NVMe or SATA. Unlike a traditional SSD form factor, an M.2 device is not hot-swappable, and its small size limits the surface area for heat dissipation which, over time, will reduce its performance and stability. In enterprise storage, M.2 SSDs often are used as a boot device. In consumer devices, such as a notebook, an M.2 SSD provides capacity expansion.

A U.2 SSD describes a 2.5-inch PCIe SSD. These small form factor devices were formerly known as SFF-8639. The U.2 interface allows high-speed NVMe-based PCIe SSDs to be inserted in a computer’s backplane, without the need to power down servers and storage.

The following video discusses the wide range of solid-state storage form factors available, as well as some benefits and drawbacks of each form factor.

SSD nonvolatile memory types

NAND and NOR circuitry differ in the type of logic gate used, with NAND devices using eight-pin serial access to data. NOR flash memory is commonly used in mobile phones, and NOR devices support 1 byte random access.

Purchasing considerations

Most all-flash arrays are available as an empty chassis or fully populated with disk, which allows customers to choose their preferred SSD to expand capacity or adapt the configuration. Several generally accepted factors deserve consideration when shopping for the most appropriate SSD.

Data protection and error correction code (ECC). NAND flash incorporates tools for detecting bit errors and repairing flipped bits. A rule of thumb is that ECC requirements increase as the number of cell levels increase.

Durability. Every SSD warranty covers a finite number of drive cycles, which is determined by the type of NAND flash. An SSD used only for reads does not require the same level of endurance as an SSD intended to handle mostly writes.

Form factor. As noted, form factor determines if a replacement SSD works with existing storage, and has implications for density — the number of SSDs that can fit in a single chassis — and whether servers have to be taken offline to replace the SSDs.

Interface considerations. SSDs communicate with a computer processor via an electrical signal. The interface determines maximum throughput and minimum latency thresholds, as well as the expansion capabilities of the SSD. Manufacturers qualify their SSDs for NVMe, SAS and SATA, with the SATA interface typically the least expensive drive type. Vendor qualifications are designed to help buyers compare devices for capacity, endurance, performance, physical size and price.

Monitoring and management tools. NVME, SAS and SATA use Self-Monitoring, Analysis and Reporting Technology (SMART) to run health checks to ensure stable performance. SMART monitoring includes things such as automated alerts and endurance reports, as well as firmware updates, resize, SSD formatting and sanitize operations.

Power usage. The drive interface also specifies the maximum power of an SSD, although many enterprise SSDs are engineered to be tuned while in operation. This feature allows users to intelligently optimize the device’s performance or power.

Power redundancy. SSDs contain a small RAM cache as a safeguard for transactional and other mission-critical enterprise data. Data is stored in RAM and subsequently written to a recently erased block of flash on the SSD. This ensures no data is lost. In addition, enterprise SSDs include multiple onboard capacitors to run the SSD and ensure writes from RAM are completed.

For consumers, the performance benefits of swapping an SSD for an HDD in a laptop probably isn’t worth the price premium, with the exception of use cases such as high-frequency trading or extensive PC gaming.

SSD manufacturers

The SSD market is dominated by a handful of large manufacturers, including Intel, Kingston Technology, Micron, SK Hynix, Samsung, SanDisk, Seagate Technology, Viking Technology and Western Digital Corp. Micron, Samsung and Seagate produce and sell NAND flash chipsets to solid-state drive vendors, and also market branded SSDs based on their own flash chips.

Storage capacity on the earliest SSDs was limited in comparison to legacy HDDs. More recently, SSD manufacturers have moved the needle by pumping out larger capacity flash drives. Intel, Micron, Samsung and Western Digital offer SSDs based on 64-layer NAND flash.

In 2018, former all-flash array maker Nimbus Data introduced a 100 TB SSD. Korean flash maker SK Hynix has claimed the densest SSD — a 72-layer 256 GB 3D NAND device.

Among established SSD makers, Samsung and Seagate are in a duel to see who wins the SSD capacity wars. The Samsung PM1643 SSDs packs 30 TB of capacity in a 2.5-inch form factor. Seagate has previewed a 60 TB SSD for enterprises.

SSD pricing

Historically, pricing for SSDs has been much higher than that of conventional hard drives. Due to improvements in manufacturing technology and expanded chip capacity, SSD prices had been dropping, allowing consumers and enterprise-level customers to re-evaluate SSDs as viable alternatives to conventional storage. That phenomenon has reversed itself several times in recent years.

The market price for SSDs is influenced by Moore’s Law, as much as supply and demand. More steps are needed to engineer a dense 3D NAND SSD, compared to the 2D NAND process. Manufacturers have struggled to increase the yields to ensure they met global demand, with mixed results in recent years.

Between 2015 and 2017, global demand for flash chips outstripped the supply. As a result, SSD manufacturers had to scramble to fill their pipelines. Fluctuating demand for flash chips has kept pricing for SSDs variable, but the price for an SSD remains higher than that of an HDD.

A June 2018 report from TrendForce, a research firm headquartered in Taipei, Taiwan, said contract prices started to fall due to an oversupply of flash chips. The resulting price drop helped to fuel increased adoption of client SSDs, including PCIe drives.

SSD vs. HDD

SSD performance is considered to be much faster than the highest performance electromechanical disk drives. Seek time and latency are also substantially reduced, and users typically enjoy much faster boot times.

A solid-state drive employs wear leveling to increase drive lifespan. Wear leveling is typically managed by the flash controller, which uses an algorithm to arrange data so write/erase cycles are distributed evenly among all the blocks in the device. Another technique is SSD overprovisioning to minimize the impact of garbage collection write amplification. This limits the usable storage on the SSD to a certain percentage.

Read performance of an HDD can suffer when data is split into different sectors on the disk. The way to repair the disk is with a technique known as defragmentation. SSDs don’t store data magnetically, so the read performance remains steady, regardless of where the data is stored on the drive. Due to their lower latency, SSDs are optimized to carry out inline data reduction with minimal impact on application performance.

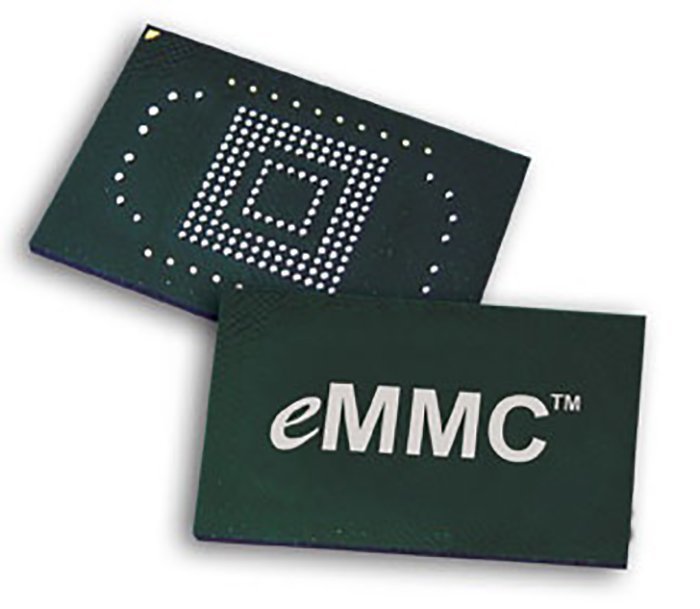

SSD vs. eMMC

An embedded MultiMediaCard (eMMC) provides the onboard flash storage in a computer. An eMMC is installed directly on the computer motherboard. The architecture, formalized by industry group JEDEC, includes NAND flash and a controller designed as an integrated circuit.

An eMMC device has fewer logic gates than an SSD, delivering performance roughly equivalent to that of an SSD. The difference is in the capacity: a standard eMMC ranges from 32 GB to 128 GB, and is, thus, unable to handle larger storage needs.

Other types of consumer flash cards used in consumer electronics include SD cards for encrypting data on digital devices, removable microSD cards for mobile phones, Secure Digital High Capacity (SDHC) cards for high-definition images and video, memory sticks for transferring photos and video files, and plug-and-play Universal Serial Bus cards that are inserted into a computer’s USB slot.

SSD vs. hybrid hard drive

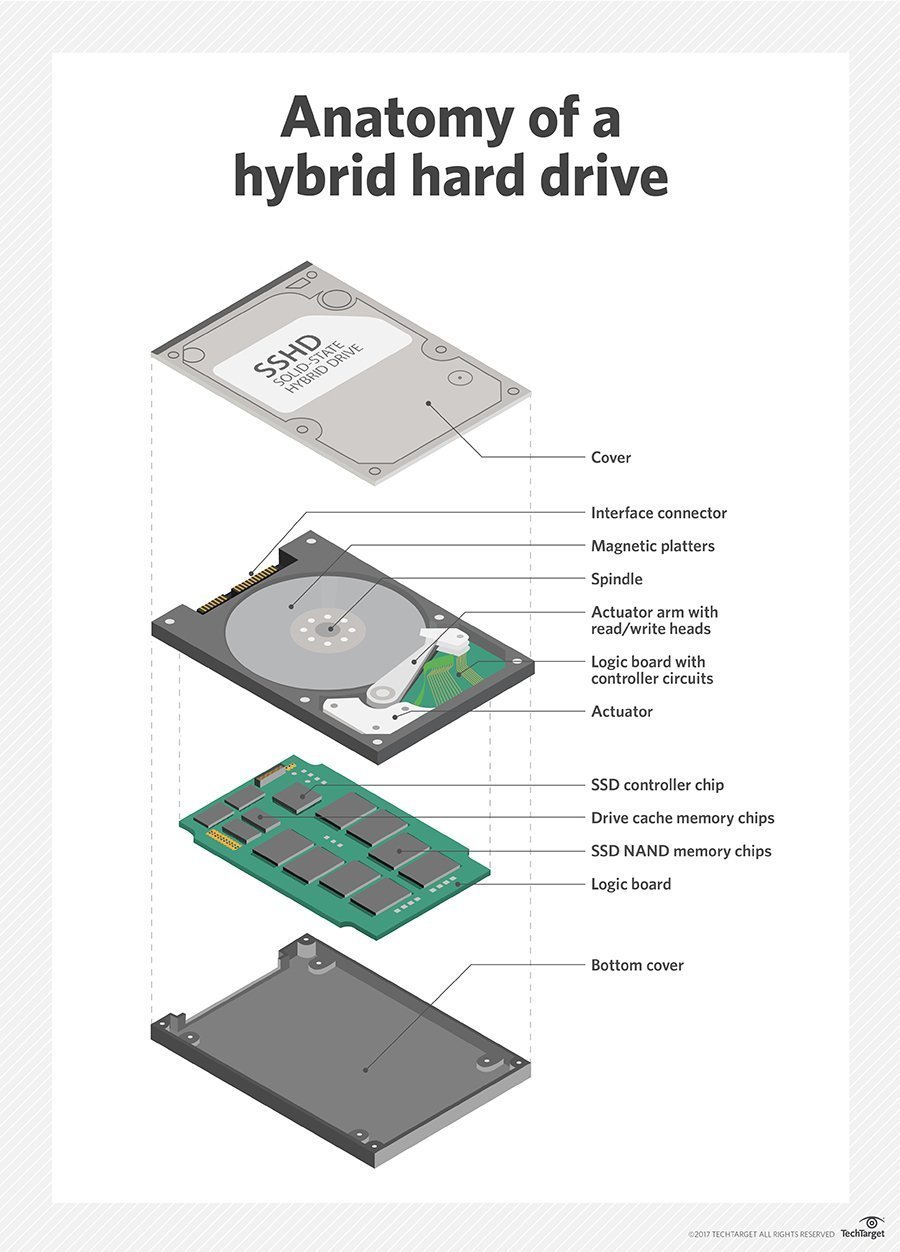

Although not as widely used as a standard solid-state drive, an alternative known as a hybrid hard drive (HHD) bridges the gap between flash and fixed-disk magnetic storage. HHDs are used as a way to upgrade laptops, both for capacity and performance.

HHDs have a conventional disk architecture that adds approximately 8 GB of NAND flash as a buffer for disk-based workloads. The HHD controller chip determines whether data is placed on the disk or the SSD module.

The emergence of all-flash storage arrays

Nimbus Data, Pure Storage, Texas Memory Systems and Violin Memory were among the startups that helped pioneer the adoption of all-flash arrays that rely on solid-state drive storage to replace hard disk. The success of all-flash startups prompted established vendors to begin selling retrofitted all-flash versions of their traditional disk-based arrays. IBM is considered to be the first major storage vendor to bring out a dedicated all-flash array platform, called FlashSystem, based on technology from its acquisition of Texas Memory Systems in 2012.

Also in 2012, EMC acquired XtremIO and now ships an all-flash system based on the XtremIO technology. Other Dell EMC all-flash arrays include the flagship PowerMax system, SC Series (formerly Compellent) and PS Series (formerly EqualLogic) systems.

Hewlett Packard Enterprise (HPE) sells all-flash 3PAR arrays, as well as Nimble Storage all-flash and hybrid SANs. NetApp all-flash arrays include the vendor’s flagship All-Flash Fabric-Attached Systems, as well as SolidFire arrays it acquired in 2015.

Dell EMC, HPE, Kaminario, Pure and SolidFire (now part of NetApp) ship all-flash systems that incorporate SSDs made with TLC NAND nonvolatile drives.

Solid-state PCIe SSDs, NVMe flash devices

Solid-state flash drives have traditionally been designed to use the SATA interface to connect storage to networked servers, using host HBAs and other components. A newer iteration of server-based flash storage involves SSDs designed for installation in PCIe slots in servers. Each PCIe-enabled SSD communicates directly with a server motherboard using a dedicated point-to-point connection, essentially eliminating resource contention and reducing latency.

SSD, PCIe or DIMM flash:

How to choose the right solid-state for your server

When selecting a caching solution, you’ll have to choose the physical flash device to leverage using the caching software. After all, it’s the combination of hardware and software that actually comprise an offering. There are three basic choices for server-side flash today:

- Solid-state drives: SSDs are the path of least resistance, but they deliver the least performance. SSDs are flash devices that come in the form factor of a traditional hard disk drive. They connect via SATA or SAS and allow for a very cost-effective first step into the solid-state world. For many environments, the performance boost from a SATA or SAS SSD will suffice.

- PCIe-based flash: PCIe-based flash is the next step up in performance. While these devices typically offer greater throughput and more IOPS, their real attraction is significantly lower latency. There are other advantages, too, including the fact that they don’t consume drive bays. The downside is that most of these offerings require a custom driver and have limited built-in data protection.

- Flash DIMMs: Flash DIMMs are yet another step up for latency reduction, going even further than PCIe flash cards by eliminating potential PCIe bus contention. But like PCIe flash cards, they require custom drivers and, unique to flash DIMMS, specific changes to the read-only memory basic I/O system on the motherboard.

SSD vendors also are developing PCIe devices around the emerging NVMe protocol, a set of specifications designed to operate at the host-controller level. NVMe specifications ostensibly aim to increase throughput of PCIe devices by streamlining the I/O stack, removing latency associated with SAS- and SATA-based SSDs.

Hybrid DRAM-flash storage

Advances in SSD manufacturing and other enhancements position the technology to play a greater role in nonvolatile storage. However, new memory channel configurations are emerging that combine flash and server DRAM. These hybrid flash storage devices are a response to DRAM approaching its theoretical scaling limit.

Another type of server-based storage deployment involves inserting flash memory in motherboard DIMM slots. Also known as in-memory storage, a flash-based DIMM does not need to traverse the PCIe controller or contend with other cards, thus lowering latency even further versus PCIe flash cards. Once considered the leading flash DIMM card supplier, Diablo Technologies brought its ULLtraDIMM and eXFlash DIMM chips to market under original equipment manufacturer (OEM) partnerships with IBM and SanDisk. Unable to sustain its business model, Diablo filed for bankruptcy protection in 2017.

Micron and Intel co-developed persistent storage — branded 3D XPoint — that claims to be as fast as DRAM yet is priced between DRAM and NAND. The first commercial product built on 3D XPoint is the Intel Optane family of SSDs.

Before its acquisition by Western Digital, SanDisk in 2015 announced a partnership with HPE to develop ReRam, also known as resistive RAM. The vendors clamed ReRam would be similar to 3D NAND flash but cheaper to manufacture than DRAM. However, prototypes from the joint project have yet to materialize, and there have been reports HPE shelved the project following SanDisk’s acquisition.

Similar ReRam initiatives are said to be under way involving Fujitsu and Panasonic, and Crossbar is trying to gain traction with ReRam technology across a range of industries, including the emerging internet of things.